Aggregate Production Minnesota State Colleges and ...

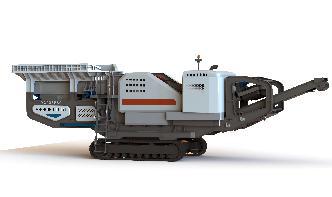

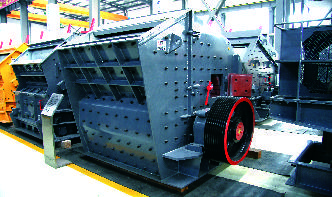

Aggregate Production. Aggregate Production This is a three day introductory course taught both in the classroom and in the lab. It covers aspects of aggregate production and quality control testing. Subjects include: prospecting for aggregate, crushing and stockpiling, aggregate blending, process control, and effects of noncomplying aggregate on...