describe the process of manufacturing of aggregates ...

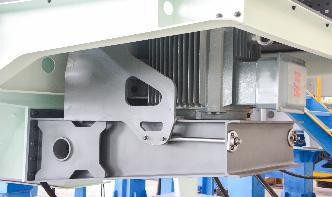

concrete crushing plant hazards → describe the process of manufacturing of aggregates. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball ...