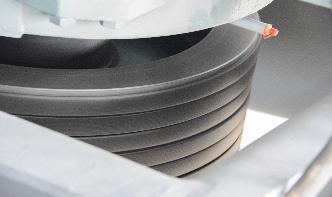

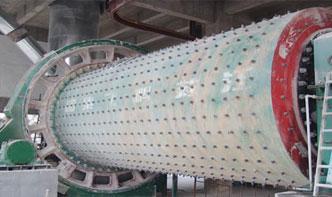

Vertical Roller Cement Mill Process Parameters

the process parameters, Vertical roller mill at present in domestic is mainly used for processing of vertical roller mill for cement factory process flow Cement Process Engineer Resume Example A cement process engineer deals with the various production stages required for the production of cement.