Cement The Environmental Literacy Council

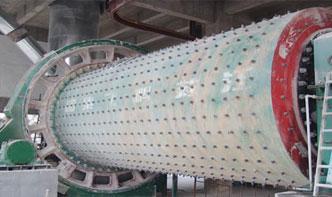

Manufacturing cement is an energyintensive process. It requires 3 to 6 million BTUs (British thermal units) of energy and tons of raw materials, mostly limestone, to make one ton of clinker. Coal or coke is typically used to fire the kilns that are used to burn the limestone, clay, shale, and other materials; the materials must be heated ...