THE I OPERATIONAL PARAMETERS ON BOILER .

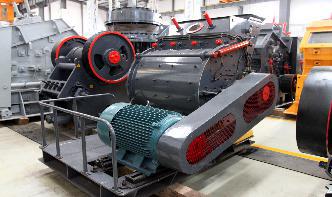

Mill outlet temperature varies in a range of 6690 oC. Capacity of each mill is 78 t/h for coal with HGI 50, 70% through 200 mesh. At design condition ... Flue gas temperature airheater outlet °C 150 Coal flow t/h Oxygen air heater Inlet % Unburnt carbon in fly ash %