Optimisation of coal fineness in pulverisedfuel boilers ...

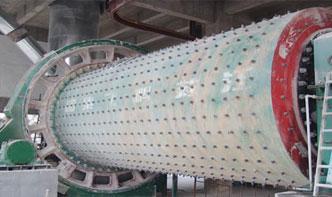

Therefore, our study presents the optimization of particles size of pulverized coal in 650 t/h pulverized coal fired boiler with natural circulation (type OP 650) to the power unit 225 MW that is equipped with ballring mills. This boiler is marked in the power plant as K6.