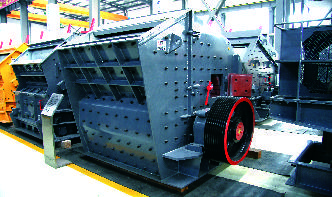

raw milling process in cement plant

Raw mill,Cement Raw mill,Grinding Raw mill,Raw ore mill Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and gla