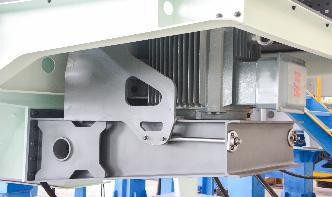

cone crusher champer

cone crusher chamber Multi Objective Planning Of Cone Crusher Chamber, the cone crusher is widely used in industry. the fundamental working principle of the cone crusher is shown in fig. 1 where a vertical cross section of the crusher is. Get a Price