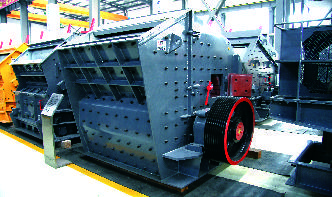

Cement/Gypsum Furnace Mineral Products Ceramic Coatings

Cement and Gypsum are energy intensive industries operating at high temperature to process raw materials into commercial products. The high temperature heating furnaces, exposed metals and refractories often experience high temperature oxidation corrosion attack and fail prematurely.