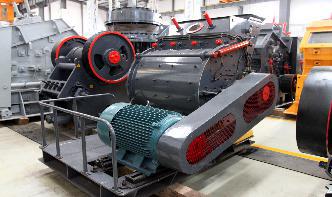

zenith coal processing plant

galvanic corrosion in coal processing plant , Jan 14, 2018· Galvanic Corrosion In Coal Processing Plant 66 Views The Zenith is the professional mining equipments manufacturer in Get More Information galvanic . More Products; coal processing plant Zenith crusherasia.