Raw material preparation. From the quarry to raw meal ...

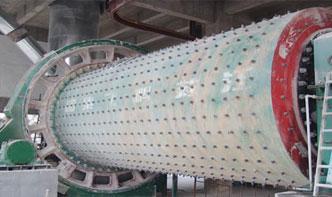

Raw material preparation. From the quarry to raw meal feeding into the preheater. A company of Polysius ThyssenKrupp ... raw materials for the cement production process is decided on the basis of ... the raw grinding plant cannot always be avoided. Even if a direct mill feeding sys