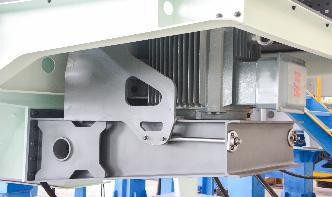

lifetime for roller in vertical roller mill

Vertical roller mill Wikipedia lifetime for roller in vertical roller mill,Overview Vertical roller mill has many different forms, but it works basically the same All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc ...