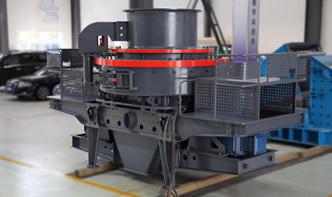

Vertical Ball Mill Maintenance Course

vertical ball mill maintenance course Grinding Mill . Vertical Ball Mill Maintenance Course. Gulin – Training in Vertical Ball Mill Maintenance Gulin's training in maintenance procedures for vertical and ball mills will. Vertimill VS Ball Mill Grinding Classification ...