Services – H H Welding

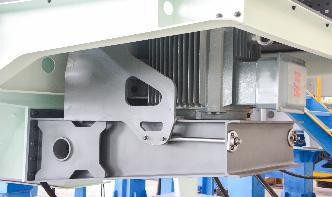

Mill capacity to 72″ ... Semi tractor frame extensions and repair welding. Trailer frame straightening and rearching. Suspension and fifth wheel plate repair and replacement. Bucket rebuilding, equipment hardfacing and crusher plant repairs. ... Refurbishment of existing dump boxes and running gear.