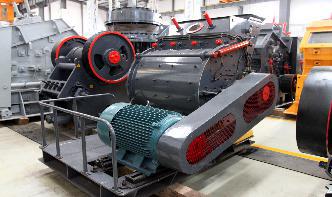

bauxite mining process crushing and grinding

Jan 24, 2018· Tantalum Ore Lead Zinc Processing Equipment Plant Silica Sand Then the ore with a proper size will be sent into the Ball Mill for fine crushing and grinding. Get Price Charcoal Crushing Machine. 2018 hard rock crusher, charcoal crushing machine, bauxite ore processing plant different diameter Charcoal Grinder and Mixer Machine Coal Grinding and