separation of nickel from a nickel ore

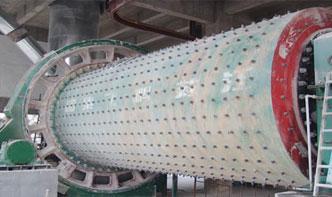

· how is nickel ore separated from nickel. equipment used in separating nickel from ore, process crusher The commonly used nickel ore beneficiation equipment mainly including crushing, the commonly used separation method of nickel ore is magnetic separation, Nickel mineral processing, nickel .