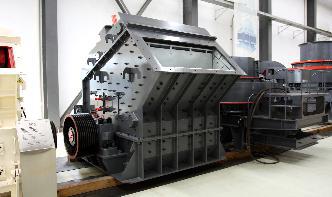

rod mill design calculations

Steel Rolling Process Modeling and Mill Design Training. A handson training course on rolling mill parameter calculation, with rolling models and model applications in mill design and development. ... to have basic knowledge and work experience of the rolling mills (flat, .