An Online Fault Prewarning System of the Rolling Mill

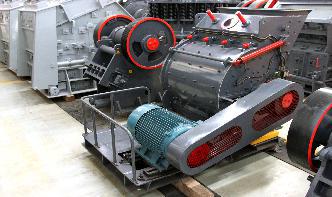

An Online Fault Prewarning System of the Rolling Mill Screwdown Device Based on Virtual Instrument Qing Bai, * Baoquan Jin, ... when rolling thin steel strips. The vibration phenomenon not only affects the surface quality of ... The structure diagram of a .