Advances in centerless grinding technology ScienceDirect

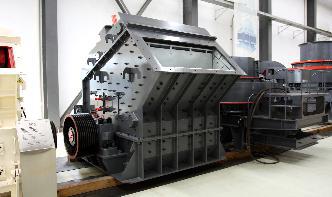

The most important invention in grinding machine development to follow the above work of Norton and Heald was the appearance of the centerless grinding machine. It was eagerly welcomed by the automotive industry, because of the high productivity and the .