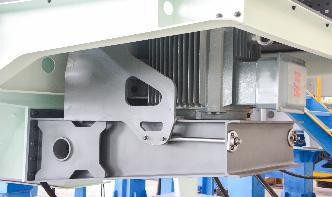

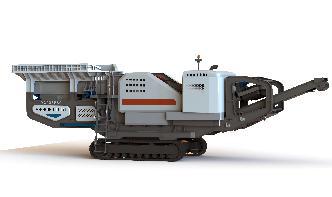

Crusher bucket epiroc

A bucket crusher can handle all types of inert material such as asphalt, stone and concrete debris as well as mine and quarry material Ideal for urban worksites Our bucket crushers can be an alternative to traditional crushers in confined areas.