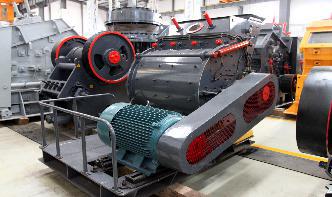

Crawler Jaw Crusher Market Size Growth, 2021 | Industry ...

A Jaw Crusher lessens large size rocks or ore by having placed the rock into compression. A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, whereas the mobile jaw exerts force on the rock by forcing it against the stationary plate.