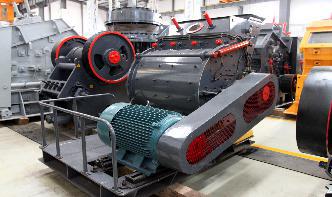

wet method raw material grinding mill

ball mill charge ball size wet grinding. wet ball mill minerals. ... Application of wet pan mill /grinding gold machine: The wet pan mill is named . The raw material should be put into the machine after the machine running normally. 2). get price>> Professional gold grinding machine,gold grinding mill for pure gold .