Why is Quarry important

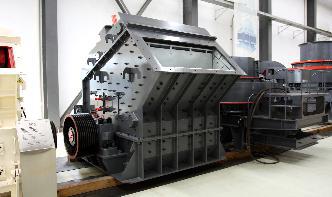

Why do we quarry? For thousands of years man has used stone for building, whether it was for monuments, religious buildings or houses. ... we still use stone in a different form for building and construction work today. ... deep pit in the ground. From a quarry, you getstone, rock, construction aggregate, riprap, sand, gravel, orslate. Marble, ...