Mining Industry: What is a grinding mill? How does it work ...

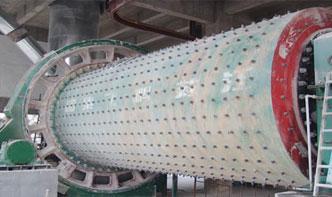

One of the most common types of grinding mill is a ball mill. This machine is typically used to grind material into powder. The ball mill uses a cylindrical container that rotates on a horizontal axis. This container is generally filled with the material to be ground, and a grinding medium, which refers to a substance that does the grinding.