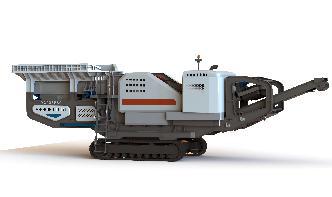

High Effective Impact Hammer Crusher For Laboratory Coal ...

coal crusher impact hammer vsinfotech the hammer crusher (hammer mill) crushes materials by the collisions between the high speed hammer and materials, and the hammer crusher (hammer mill) features are in its simple structure, high reduction ration, high efficiency, etc.